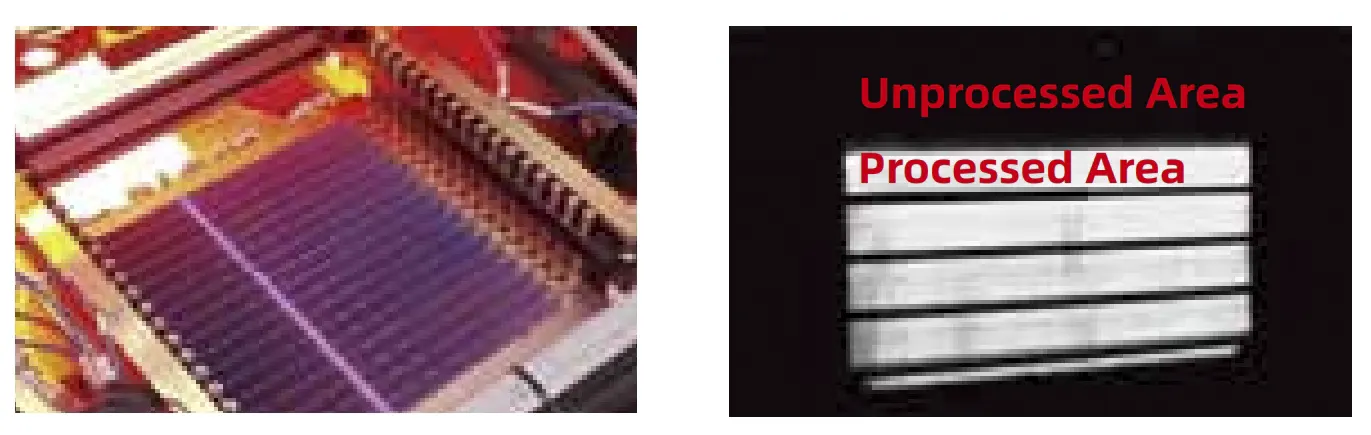

Single laser to precisely destruct the passivation layer on the silicon wafer surface, optimizing metal contacts and reducing contact resistance to improve the efficiency of solar cells; suitable for TOPCon, xBC, half-cut, third-cut, 0BB cells, and other processes.